Discovered a local supplier for silicone flanges/gaskets and got to see a Cool Cnc machine in action. Also been working on the 'sourcing' aspect and realised what a crazy big markup hardware stores have. I suppose it's ok for little jobs here and there but if you want to make 10, 100 or 1000 showers there are apparently much better ways to do it. Finding local commercial suppliers I managed to drop the price of parts by maybe 50e in 10 minutes :)

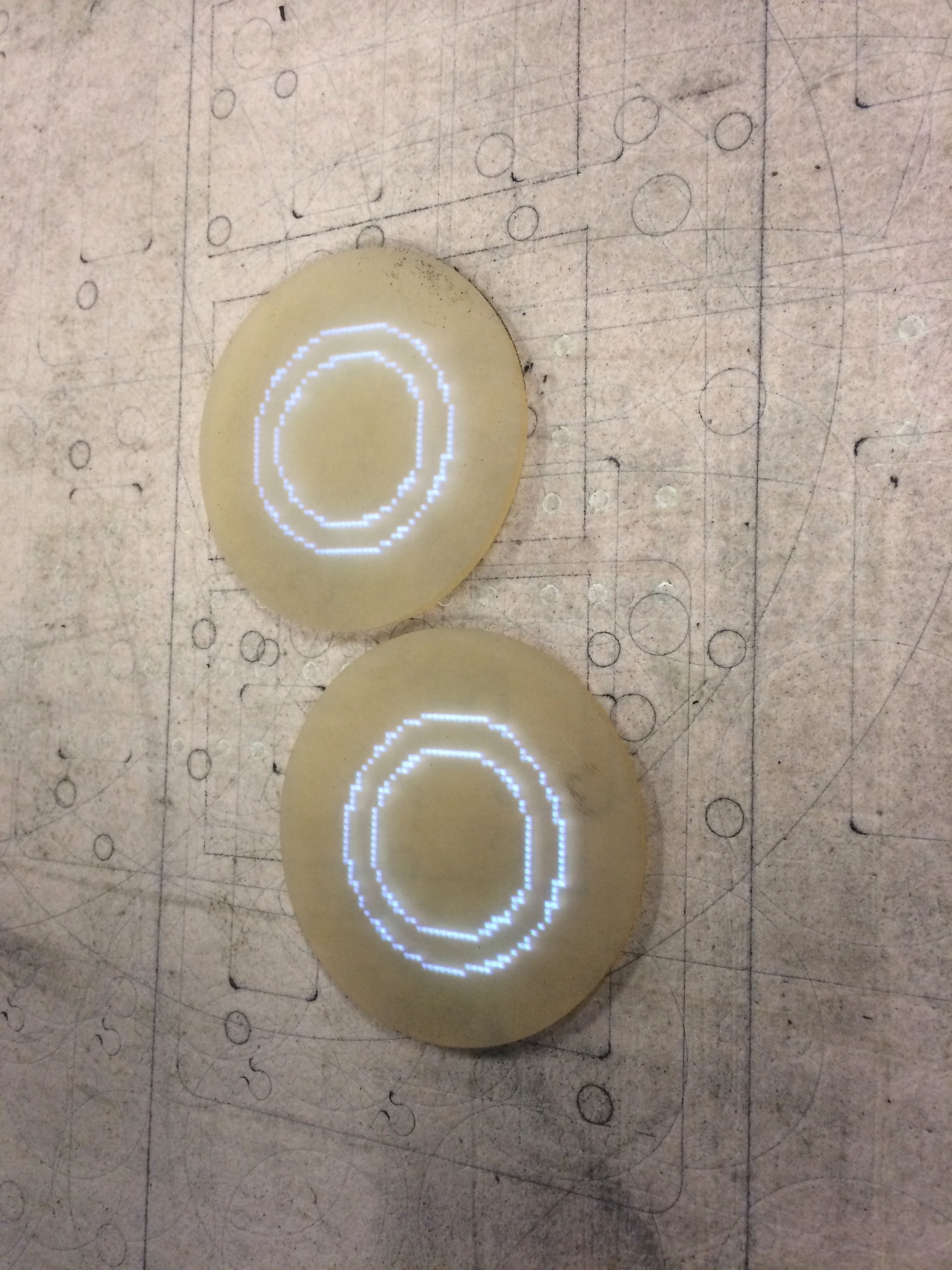

Projectors from the top of the device are used for tracking so all the technician had to do (actually he let me do it) was throw down the silicone material where the cool pixel circle was.

The projector is bouncing the image on the mirror/glass top left

Plastic to increase suction on the vacuum table below to hold the flanges in place while cutting.